Natural stone processing

Some of the most common types of Natural stone processing include stonemasonry and carving, sawing, turning, casting, polishing, and engraving.

What is dry stone processing?

Dry stone processing is a method of working with stones that relies on the use of hammers and other tools to shape, cut or shave them without the use of water or abrasive materials.

What is wet stone processing?

Wet stone processing is a technique in which stones are worked on using wet grinding or polishing with grinding wheels or circular discs, this technique allows for a smoother and more polished surface than dry processing.

Types of stone processing

There are different processes for polishing stones that have different implementation methods, some of them are mentioned below.

- Flame or Thermaling

- Bush Hammered

- Bush Hammered + Brushed

- Polished

- Honed

- Brushed

- Sandblasted

- Sandblasted Brushed

- Acid Wash

- Split

- Broken Cut

- Tumbled

- Chisel Edge

Construction stone processing

Natural stone processing is a set of methods used to remove minerals from ore mined out of the ground, the process involves breaking large pieces into smaller pieces called blocks and then crushing or grinding them until they are of the same size. Small enough to be used, the stones can then be cut into different shapes and sizes depending on the intended purpose. These cuts can include the cutting of decorative gemstones in the creation of jewelry, statues or sculptures with all the details.

Stone processing is one of the basic operations in stone preparation, building stones consist of different categories, each of which is suitable for a part of the building. There is a point in building architecture that each stone is used in its own space according to its color, material and application. In order to use stones in different spaces of the building, according to the space that is supposed to be used there, payments should be made on their surface.

It should be noted that during the processing of building stones, depending on their application, resins of the same color, cement, etc. can be used. For example, one of the characteristics of travertine stone is the presence of holes in them. Some people prefer to use this stone naturally with the same porosity, but there are also people who want this porosity to be covered and the surface of the stone to be completely smooth and polished. In this case, resin is used to fill these holes.

Construction stone processing steps

First step : cutting construction stone

- Cut with a saw

- Cutting with a cutter

- Cutting with a wire cutter

The second step: Strengthening the stone

The third stage: stone work resin

Step 4: Grinding in the construction stone processing stages

The fifth step: edging the stone

* The steps of processing building stones in Negin Stone are presented in the above order and in the following ways.

Flame or Thermaling

In this processing method, the obtained stone has an uneven, non-slip surface, and its color is generally faded, thus hiding its defects and changes. The film process can be applied well on granite stones.

The flame or heat method is a stone processing method that is achieved by directly exposing the stone surface to a high temperature flame. In this method, as the name suggests, the use of hot torch flames and its movement on the surface of the stone causes expansion and flaking of the upper part of the stone, and the surface of the stone becomes uneven.

Bush Hammered

In this method, they hit the stone using a machine or by hand, which creates holes on the stone and grooves the stone. Today, this work is very common to create an uneven surface on stone and it can be done on granite, travertine, marble and porcelain.

Bush-Hammered + Brushed

In this method, they hit the stone just like the previous method, which creates holes on the stone and grooves the stone, with the difference that after axing, the stone is Brushed, which changes the surface of the stone from the previous state and condition. It pulls out a little unevenly, but the holes and grooves are preserved.

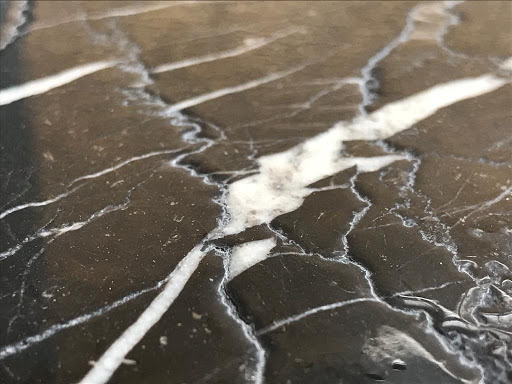

Polished

This process is one of the most common processes performed on stone. This is a method in which stones that have an uneven surface are turned into highly polished and attractive stones using machines. In this method, after being cut, the stone enters various sub-machines and this machine makes the stone polished and looks more polished and beautiful.

Honed

In this method, the surface of the stone is practically rough and does not have a final roughness and is not completely polished. Also, these surfaces are matte and not shiny. In high-traffic areas, floors are often shaved and basically use this type of processing to effectively prevent people from slipping.

Brushed

Brushing or leather work in this method, instead of using normal brushes to grind the polished surface, special leather brushes are used in the SAB machines, which have a greater effect on the weak points of the stone, and for this reason, those parts eat more SAB.

Sandblasted

Sandblasting is a combination of the two words sand and blasting, in this method by pumping abrasive materials (such as sand) with high pressure on different surfaces, a transparent surface is created and it also creates holes or cavities on the stone that can cause Increase friction.

Sandblasted Brushed

In this method, like the previous method, after sandblasting the stone, it is turned into Brush, which makes the surface of the stone come out of roughness and the original and natural color of the stone is completely defined.

Acid Wash

In this method, the surface of the stone is covered with a strong acid for 15 to 30 seconds (according to the hardness of the stone), this makes the surface of the stone look old and rough, which is mostly used for floors.

Split

In this method, the stone is turned into two halves using a machine, which creates natural bumps and depressions on the surface of the stone. This processing is mostly used for sidewalks and landscaping.

Broken Cut

In this method, the surface of the stone will be carved into a groove for more beauty and polish, which is implemented in different designs and sizes.

Tumbled

This process can be applied both by machine and by hand, in this process, the corners and edges of the stone are worn, and the longer the stone is placed in the machine, the more the wear and roundness of the corners will be.

Chisel Edge

In this method, the edges and corners of the stone are worked on like the tumbled processing, with the difference that the edges are filled and have a broken state.